Hall Effect Current Sensor

Product Details

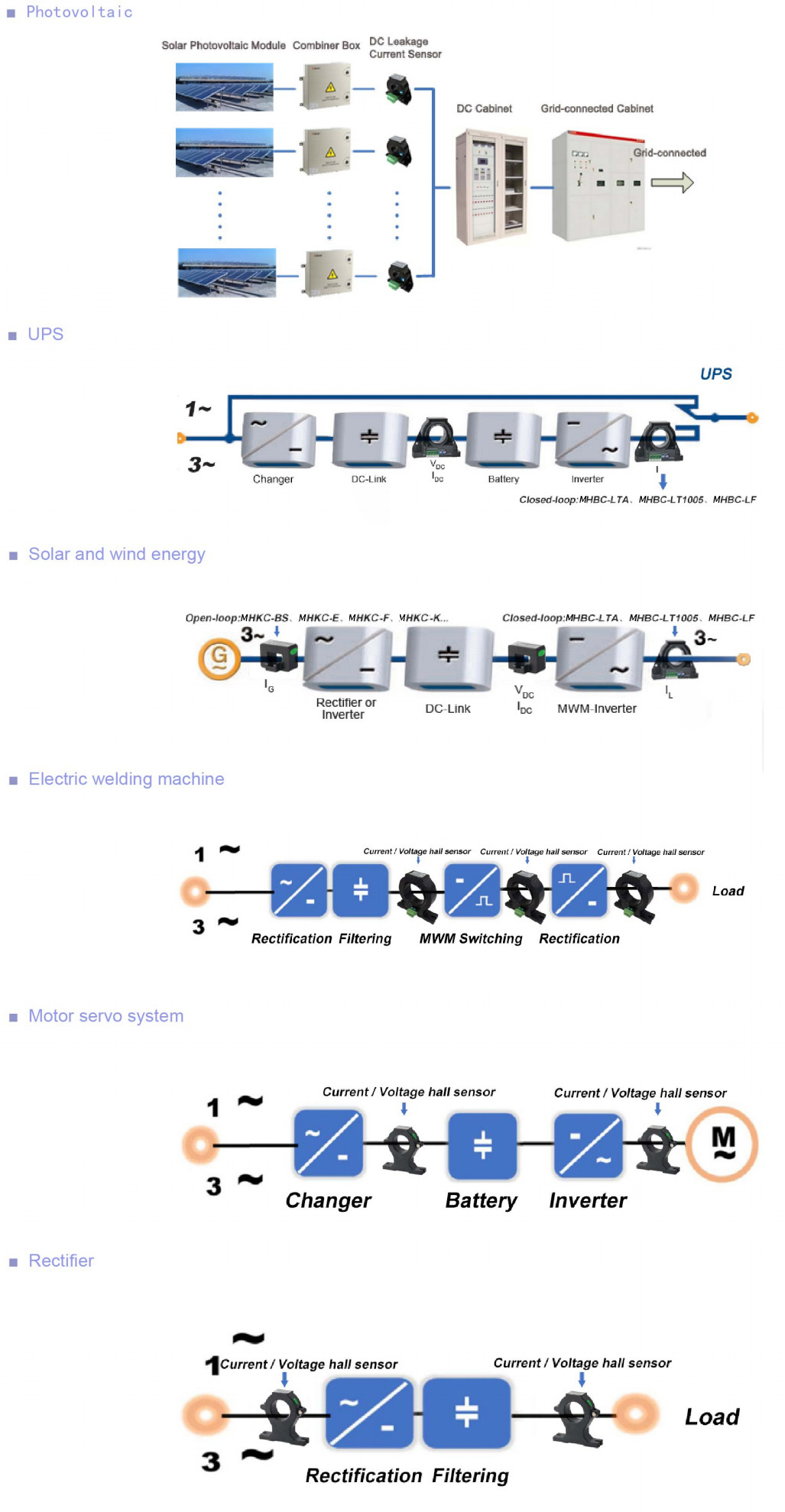

Application

★ Industrial control

★ Energy and Automation

★ Automotive

★ Railway

Structure

Main Functions

|

Type |

Function |

|

Open loop Hall sensor |

1.Class1 |

|

Closed loop Hall sensor |

1.Class0.5 |

|

Hall voltage transducer |

1.Class0.5 |

Product selection

|

Type |

Rated Input |

Rated Output |

Measuring Aperture |

Power Supply |

Application |

|

MHKC-EKA |

0-(50-500)A |

5V/4V |

20mm |

±15V |

1.Photovoltaic |

|

MHKC-EKAA |

DC 0-(50-500)A |

4-20mA |

20mm |

12V/24V |

|

|

MHKC-BS |

0-(50-500)A |

5V/4V |

20.5*10.5mm |

±15V |

|

|

MHKC-F |

0-(200-1000)A |

5V/4V |

43*13mm |

±15V |

|

|

MHKC-K |

0-(400-2000)A |

5V/4V |

64*16mm |

±15V |

|

|

MHLC-LTA |

100A-300A |

50mA/100mA |

20mm |

±15V |

UPS |

|

MHBCIF |

2000A |

400m4 |

/ |

±12V~+24V |

1.UPS |

|

MHBC-LT1005 |

1000A |

200mA |

/ |

±12V~±24V |

UPS |

Hall Effect Current Sensor: An Innovative Solution for Current Measurement

The Hall Effect Current Sensor has emerged as a highly reliable and efficient device for measuring electrical current in a wide range of applications.

1. Principle of the Hall Effect

At the core of the Hall Effect Current Sensor is the Hall effect, which was discovered by Edwin Hall in 1879. When a current - carrying conductor is placed in a magnetic field perpendicular to the direction of the current, a transverse electric field is generated across the conductor. In a Hall Effect Current Sensor, this principle is utilized to measure the magnetic field associated with the current flowing through a conductor. A semiconductor material, often with specific properties optimized for Hall effect sensing, is used as the sensing element.

2. Structure and Components

These sensors typically consist of a Hall - element, which is the heart of the sensor and responsible for detecting the Hall voltage. The Hall - element is often integrated with other components such as a magnetic core, which concentrates the magnetic field around the current - carrying conductor. There is also associated circuitry for signal conditioning. This circuitry amplifies and processes the relatively small Hall voltage signal generated by the Hall - element into a usable output signal, which can be either an analog voltage or a digital signal depending on the type of sensor.

3. Key Features

Non - invasive Measurement: One of the significant advantages of Hall Effect Current Sensors is that they can measure current without the need to break the circuit or make electrical contact with the conductor carrying the current. This non - invasive nature makes them ideal for applications where it is not practical or desirable to interrupt the circuit, such as in live - wire measurements in electrical systems.

Wide Measurement Range: They can measure a wide range of currents, from a few milliamperes to thousands of amperes. This versatility makes them suitable for applications in various industries, from small - scale electronics to large - scale industrial power systems.

High Accuracy: Hall Effect Current Sensors are known for their high - accuracy measurement capabilities. The accuracy can be as high as a fraction of a percent, depending on the quality and design of the sensor. This high accuracy is crucial in applications where precise current measurement is required, such as in battery management systems, motor control, and power monitoring.

4. Applications

Automotive Industry: In modern vehicles, Hall Effect Current Sensors play a vital role. They are used in battery monitoring systems to ensure the proper charging and discharging of the vehicle’s battery. They are also employed in motor control systems for electric motors, such as those used in electric windows, windshield wipers, and electric power steering. By accurately measuring the current flowing through these motors, the sensors enable precise control and protection against over - current conditions.

Industrial Automation: In industrial settings, these sensors are used for power monitoring and control. They can be integrated into power distribution systems to measure the current flowing through different branches of the circuit. This information is then used for load balancing, energy management, and fault detection. For example, in a factory with multiple machines, Hall Effect Current Sensors can monitor the current consumption of each machine, allowing operators to optimize energy usage and detect any abnormal current consumption that may indicate a malfunction.

Renewable Energy Systems: In solar and wind energy systems, accurate current measurement is essential. Hall Effect Current Sensors are used in inverters, which convert the DC power generated by solar panels or wind turbines into AC power for the grid. By measuring the input and output currents of the inverter, these sensors help in optimizing the conversion efficiency and ensuring the safe and stable operation of the renewable energy system.

5. Future Trends

As technology continues to advance, Hall Effect Current Sensors are expected to see further improvements. Miniaturization is a trend, allowing them to be used in more compact electronic devices. Additionally, the integration of intelligent features such as self - calibration and wireless communication capabilities is on the rise. This will enable more convenient and efficient use of these sensors in Internet of Things (IoT) - based applications, where seamless data transfer and remote monitoring are becoming increasingly important.

In summary, the Hall Effect Current Sensor is a powerful tool for current measurement, offering a combination of non - invasive measurement, wide measurement range, high accuracy, and diverse applications in various industries.

Keywords: Hall Effect Current Sensor

Online Message

Recommended Products

Recommended products

Tel: +86-17755160811

Email: Sherry.fu@3moretech.com

Address: Building A1, Liheng Industrial Plaza II, Economic Development Zone, Hefei, Anhui,China

Copyright© 2024 Hefei 3more Intelligent Technology Co., Ltd. All Rights Reserved